Summary Highlights:

- Rooftop installations can disrupt drainage, insulation, and membrane performance.

- Improper layout planning can lead to long-term structural damage and water pooling.

- Equipment curbs, supports, and penetrations must be carefully sealed and integrated.

- Professional roof inspection services help avoid design conflicts and costly failures.

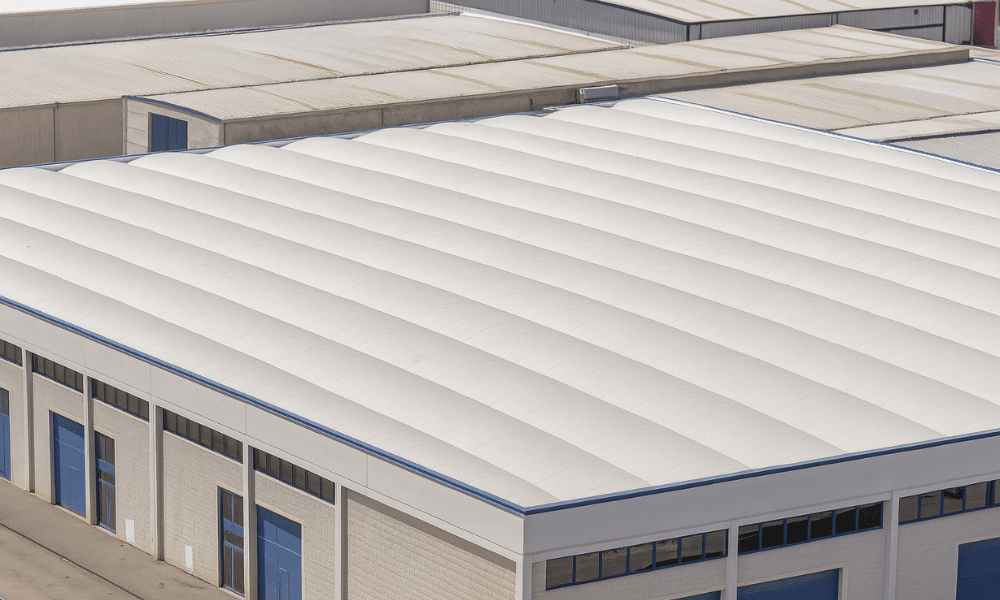

If you're designing or renovating a commercial roof with equipment like HVAC units, satellite dishes, or solar panels, it's not just about where they fit; it's about how they affect your entire roofing system. At WaterTight Roofing, we've worked with facility managers, architects, and builders to design intelligent roof layouts that maximize performance and reduce long-term liability. Let's explore the critical design choices that can protect your investment and extend the life of your commercial roof.

Why Does Rooftop Equipment Require Special Design Planning?

Every piece of rooftop equipment—from an exhaust fan to a 10-ton HVAC unit—impacts your roofing system. Their weight, placement, and maintenance requirements can create vulnerabilities in your membrane, insulation, and support structures. At WaterTight Roofing, we assess how these elements affect load distribution, roof slope, and waterproofing so we can design a solution that's both functional and durable.

Rooftop layouts must consider:

- wind uplift pressures around large equipment

- shadowing effects on solar panels or reflective membranes

- accessibility for maintenance teams

- expansion and contraction from temperature swings

Even seemingly minor components like piping or conduit runs can cause penetrations that, if not properly flashed and sealed, can compromise your roof's integrity. That's why our design reviews always take a holistic approach to rooftop equipment planning.

How Can Equipment Placement Affect Drainage and Waterproofing?

Rooftop water management is one of the most overlooked elements of commercial roof design—and yet, it's the leading cause of premature roof failure. Equipment footings, support frames, or cable trays can obstruct drainage paths or create low spots where water collects.

Our roof and drainage inspection process goes beyond checking for ponding; we evaluate how equipment interacts with the slope and drainage points. In some cases, the installation of one new piece of equipment can necessitate new crickets, scuppers, or tapered insulation design to ensure proper runoff.

When we identify drainage interference risks early, we can redesign slopes or reposition components. This proactive approach protects your warranty and your budget while reducing the risk of leaks and mold intrusion.

What Structural and Safety Factors Should Be Considered?

Many commercial roofs weren't originally designed to hold heavy or dynamic rooftop systems. Equipment that vibrates, shifts during storms, or concentrates weight in small areas can damage decking or cause deflection. Code compliance is another concern—especially for platforms, walkways, or mechanical screens that alter wind dynamics.

At WaterTight Roofing, we collaborate with engineers and installers to ensure that structural loads are distributed properly, anchors meet code requirements, and all support systems integrate with the membrane without voiding your warranty.

We also address access safety. Rooftop equipment requires periodic service, which means pathways, tie-offs, and safety railings must be part of the design. We help you plan OSHA-compliant systems without compromising membrane protection or drainage function.

How Do Inspections Support Better Design Outcomes?

The earlier our expert commercial roof inspectors are brought into the design or retrofit process, the better we can help avoid missteps by allowing us to:

- Identify conflicts between equipment placement and roof slope.

- Check existing membrane and insulation conditions.

- Plan penetrations to avoid deck seams or expansion joints.

- Verify that equipment installs won't stress flashing systems

Inspections don't just benefit new construction—they're also vital when repurposing a facility or upgrading older rooftop units. Whether you're adding RTUs, telecom gear, or solar, our inspections provide a roadmap that keeps your roof system watertight and efficient for years to come.

What's the Long-Term Impact of Improper Rooftop Integration?

The real danger with poor rooftop equipment design is the slow buildup of damage. Even a small misalignment or missed seal can lead to moisture intrusion, insulation degradation, and, ultimately, structural problems. Over time, you could face issues with interior leaks, rising energy costs, or full membrane replacement—all of which are preventable.

That's why we emphasize working with an experienced commercial roofing partner. At WaterTight Roofing, we bring not just installation knowledge, but system-wide insight that helps you protect every layer of your investment. With every project, we prioritize sustainable designs, compatible materials, and future-ready layouts.

Who Should You Partner With to Ensure Equipment and Roofing Work Together?

The relationship between your rooftop equipment and your roofing system isn't just about coexistence—it's about collaboration. The best results come from early integration between your roofing contractor, MEP engineers, and equipment vendors. This ensures a seamless transition between design, installation, and long-term maintenance.

Our team at WaterTight Roofing specializes in complex commercial roofing scenarios. We've helped clients across retail, industrial, and institutional sectors develop designs that are compliant, durable, and cost-effective. Whether you're planning a rooftop chiller, solar array, or communication system, we're ready to ensure your roof supports—not suffers from—your upgrades.

Don't let poorly planned rooftop equipment cut your roof's life short. Call WaterTight Roofing today at 888-809-9976 and let's build a roofing strategy that's engineered for performance, safety, and long-term ROI. With the right partner, your rooftop can do more than hold equipment—it can hold value.

FAQs About Commercial Roofing Inspection

Blog subscribers get new resources and how-to guides delivered via email.

Your Business Relies On Staying Dry